Our Customers

Many domestic metal factories take goods from us

About Us

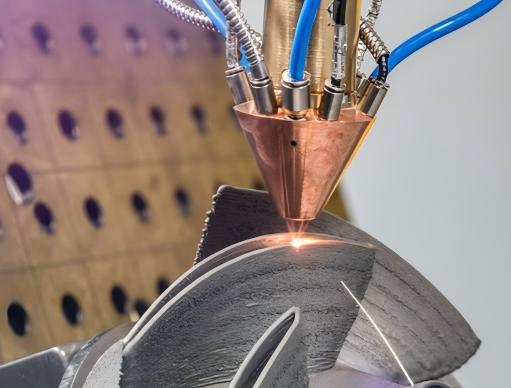

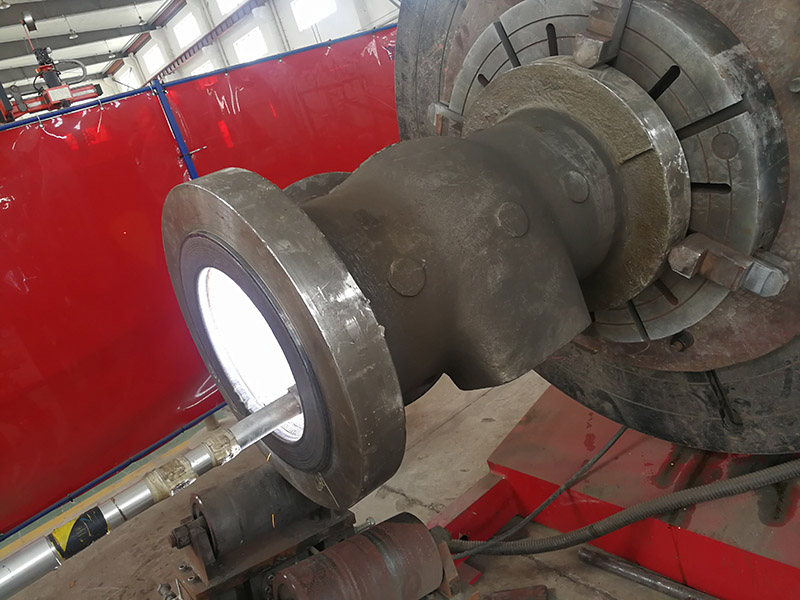

Founded in 2016, FNS (Nanjing) Surface Engineering Technology Co., Ltd. is a global leader in the cladding industry for pipeline systems, specializing in providing high-precision, wear-resistant, and corrosion-resistant cladding products and technical services for industries such as oil & gas, chemical processing, and marine engineering. Our expertise extends beyond pipes, flanges, elbows, and tees to high-end manufacturing applications in mining machinery and new energy equipment, helping clients tackle extreme working conditions.

With over 100 cladding systems FNS has achieved an annual welding wire processing capacity of 200+ tons. Our vertical cladding equipment production ranks among the top in China, and our actual production output leads the nation.

FNS has consistently pursued independent innovation, securing 61 intellectual property rights, including 7 invention patents, 25 utility model patents, and 1 software copyright in the fields of cladding materials, equipment, and applications. We are a certified National High-Tech Enterprise, a Jiangsu Private Technology Enterprise, a Nanjing Gazelle Enterprise, and a Specialized & Innovative SME at the provincial level.

Case Studies

-

A laser cladding rotary tiller blade is an upgraded agricultural cutting tool designed for high-load, long-duration field operations. By applying laser cladding technology to the blade surface, [...]

-

The paper manufacturing industry relies heavily on equipment that operates under continuous friction, humidity, pressure, and chemical exposure. Key components such as press rolls, doctor blades [...]

-

Mining environments expose coal cutting picks to extreme impact, abrasion, and continuous friction. To improve durability and operational safety, plasma hardfacing has become one of the most eff [...]